Megasonic tanks

Tanks for every application

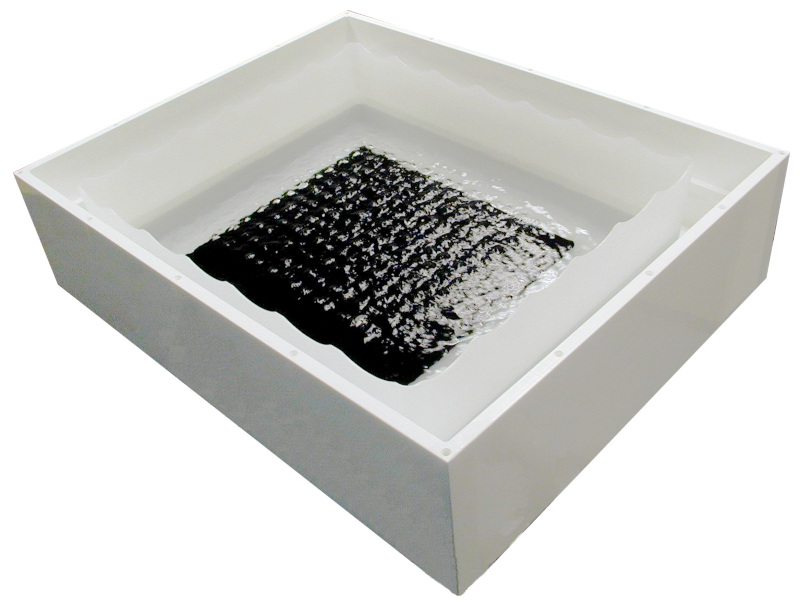

Tanks for use in wet processes are available in various designs, e.g., in stainless steel or PVDF. The Megasonic transducer plate is integrated by screwing or welding it in place, thus becoming an integral part of the tank.

The integration of the plate is defined by a cutout as an interface and installed at SONOSYS®.

The requirements of the medium used (chemicals) usually determine the material used, both for the tank and for the coating of the megasonic transducer. We would be happy to advise you on the available options and can also assist with the procurement of the tank if required.

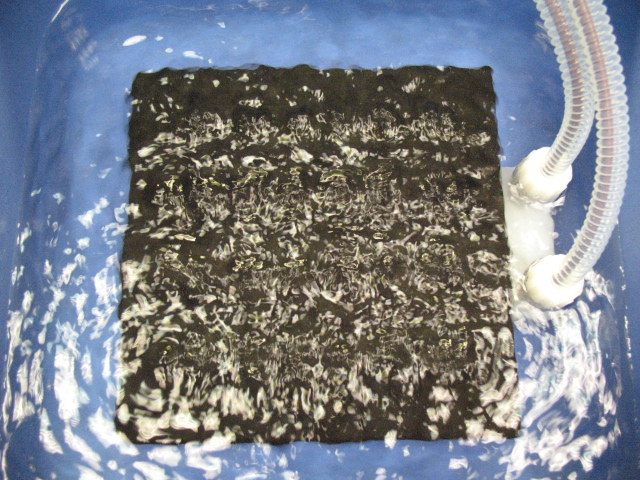

Example application:

The megasonic system has been specially developed for use in wet processes in the production of semiconductor wafers, in particular for SC1 and SC2 cleaning processes, as well as “final rinse” applications in the temperature range from 20°C to approx. 75°C for wafers up to 300mm.

Transducer plates

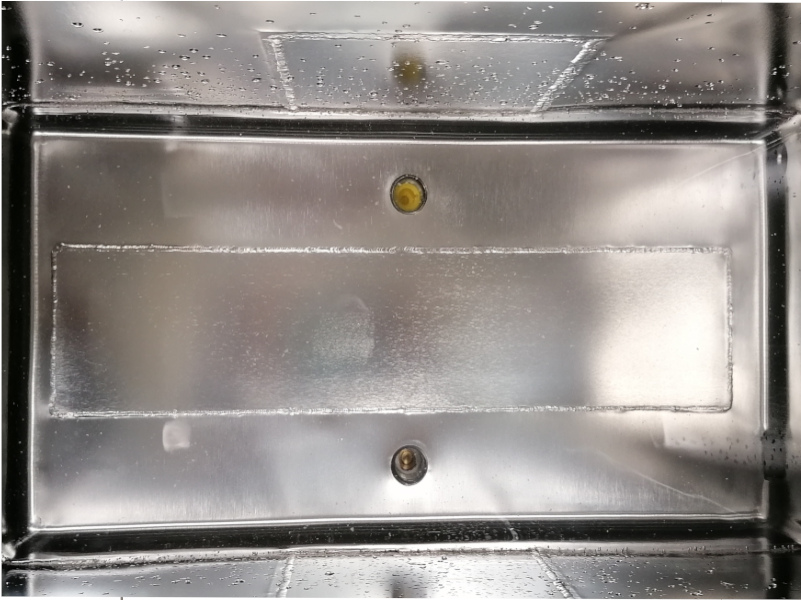

Solutions for installation in stainless steel and plastic tanks

Stainless steel transducer plates for installation in process tanks can be coated with PFA for use in plastic tanks.

In addition to the standard versions for substrate sizes of 4“, 6”, 8“, or 12”, the dimensions can also be customized. The cutout for the plate is determined jointly during the design phase and then welded or screwed in later. This allows for space-saving and suitable integration of the transducer plate into the respective tank.

Application:

Cleaning of semiconductor wafers with sizes of 100 mm, 150 mm, 200 mm, and 300 mm in single or dual carriers.